Froeb-Verpackungen GmbH is Europe's leading manufacturer and developer of environmentally friendly ESD packaging. The secure and precisely fitting ESD packaging is manufactured in accordance with DIN EN 61340-2-3.

For the storage and shipping of electrical, electronic, optoelectronic, and electrostatic-sensitive components, we produce ESD packaging that protects these products from electrostatic discharge. This prevents damage caused by discharges, which can lead to material changes and functional malfunctions or even complete destruction of the component. We produce ESD packaging for printed circuit boards, high-frequency circuits, microelectronic components, diode lasers, light-emitting diodes, computer components, circuit boards, sensory measuring devices, screens, and LEDs, among other things.

In addition to manufacturing standard antistatic packaging, we also produce inserts for these so that assemblies or circuit boards can be packaged and shipped quickly and safely. To this end, we have developed foam insert systems and film insert systems that can be individually adapted to the product size and thus securely package electronic components in large quantities with minimal use of material. We also offer environmentally friendly inserts made from a combination of cardboard and paper. These include ESD compartments made from solid and corrugated cardboard, as well as our newly developed meander packaging made from antistatic packing paper.

Environmentally friendly alternative to plastic packaging

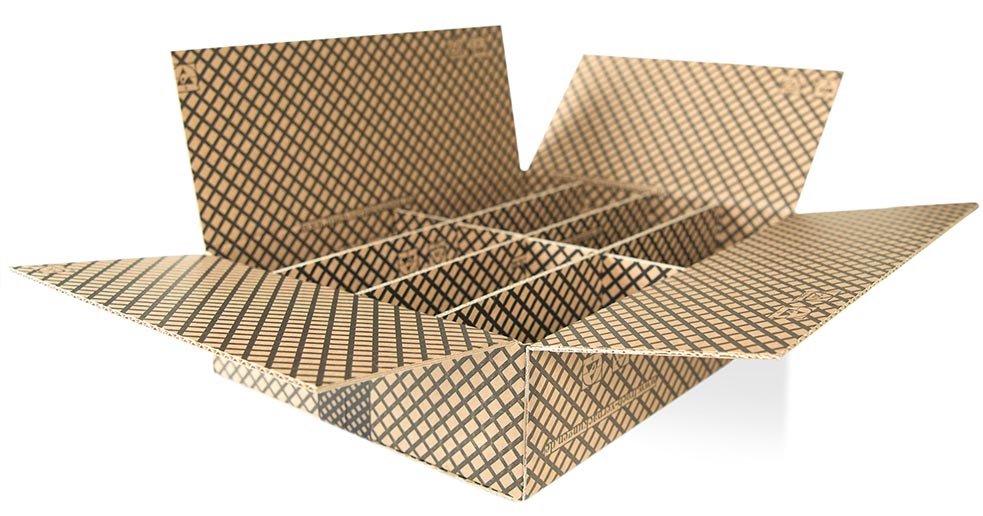

ESD packaging is traditionally made from plastic. However, cardboard packaging can also be used for antistatic packaging. We manufacture ESD cardboard boxes from solid board and corrugated cardboard, which have an antistatic effect thanks to a special coating. ESD cardboard boxes therefore offer a genuine, environmentally friendly alternative to plastic ESD packaging, as they provide just as effective protection against electrostatic discharge,

as plastic packaging and are also made from recycled material, which means they can easily be returned to the recycling cycle. Due to their stability, antistatic cardboard boxes can also be reused as reusable packaging. They can be supplemented with compartment inserts and foam elements, thus offering optimum protection for electronic components.

In addition to manufacturing standard antistatic packaging, we also produce customized packaging that is tailored to the product characteristics of electronic components and assemblies as well as the area of application. In addition to shipping electronic components in ESD packaging, ESD cardboard boxes can also be used as storage boxes. For this purpose, we produce, for example, custom-fit ESD storage boxes for storage lifts,

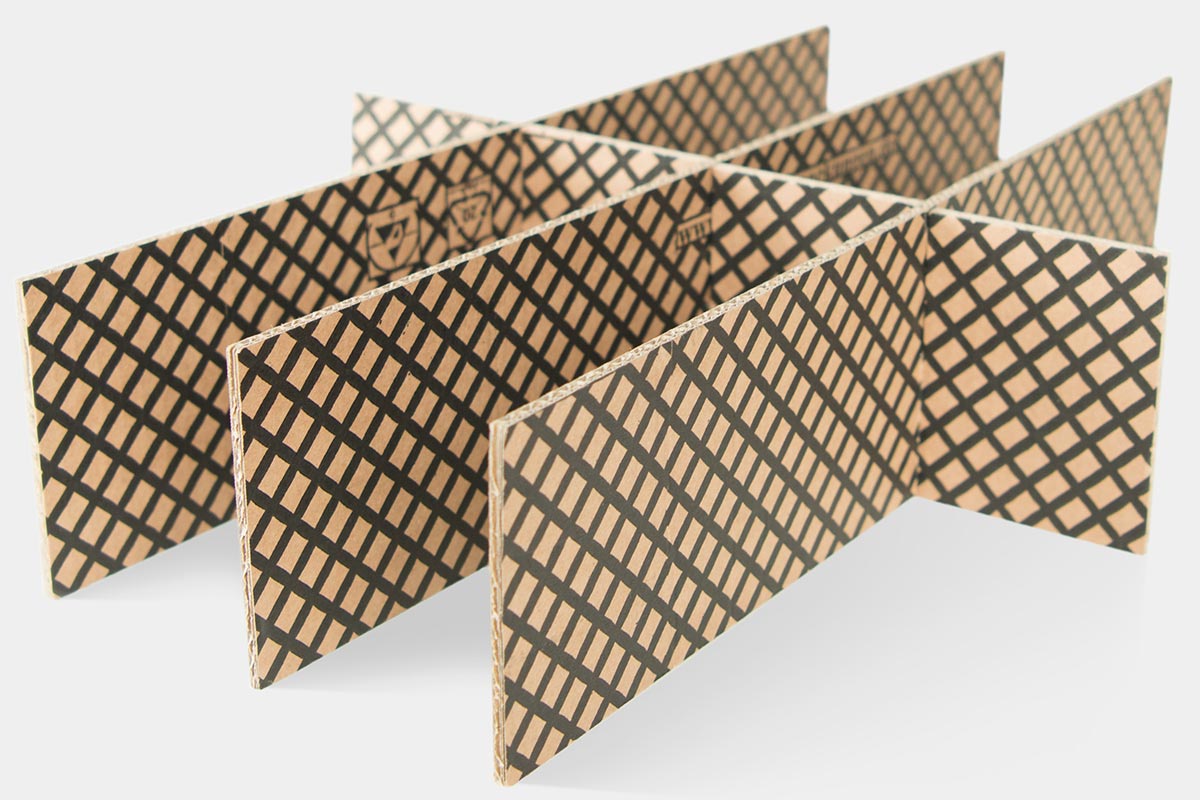

in order to make the most effective use of storage space. Antistatic cardboard boxes can also be manufactured much more cost-effectively than carbon fiber-coated plastic containers. With a supplementary inlay of antistatic compartment inserts, even small products can be packaged and stored quickly, space-savingly, and clearly.

Packaging with compartments made of solid cardboard is impressive in terms of environmental protection and production costs. It is manufactured using fresh fibers from recycled material, making it environmentally friendly and conserving resources. They can be 100% recycled, and a major advantage is that they take up very little space when folded, which is particularly noticeable when purchasing larger quantities. In addition, unlike corrugated cardboard compartments, they produce less dust and are therefore more suitable for the electronics sector. They are preferably suitable for smaller compartments, as stability decreases with increasing size. No tools are required for the production of solid cardboard compartments, which means that no additional tool costs are incurred for subsequent adjustments and production costs can therefore be kept low. The raw material is also cheaper than corrugated cardboard or plastic.

Conclusion: ESD packaging with solid cardboard compartments is suitable for small and medium-sized packaging that needs to be environmentally friendly. They are space-saving and can be manufactured cost-effectively.

In addition to solid cardboard, corrugated cardboard is also used in the manufacture of ESD compartments. These are also produced with the addition of fresh fibers from recycled material and are therefore also environmentally friendly and resource-saving. They can be 100% recycled.

Corrugated cardboard is also well suited for use in larger packaging, as it is more stable than solid cardboard. One disadvantage, however, is that corrugated cardboard leads to greater dust exposure.

Corrugated cardboard compartments can also be manufactured without tools. However, productivity can be increased for larger purchase quantities by using a punching tool.

Conclusion: ESD packaging with corrugated cardboard compartments is very versatile and, due to its stability, is also suitable for larger packaging. Products can be packaged in an environmentally friendly and economical way.

The advantages of ESD packaging made from plastic are clear in terms of stability and weather resistance. Even large packaging can be produced without compromising stability. Thanks to their weather resistance, the packaging can also be reused several times without any problems and can even be described as resource-saving in terms of reusability. Unlike cardboard, plastic ESD packaging does not produce dust and is therefore very well suited for use in the electronics sector. However, the raw material is more expensive than solid or corrugated cardboard and productivity during die cutting is lower, which means that a tool is usually always required for production. Plastic ESD packaging is difficult to recycle and therefore less environmentally friendly.

Conclusion: Due to their stability, ESD packaging with plastic compartments is also suitable for large packaging. It is weather-resistant, low-dust, and can be reused multiple times without any problems.

Plastic compartments made of solid material are also used in the electrical industry. These antistatic solid plastic compartments are particularly suitable for packaging and storing electronic components such as circuit boards, LEDs, etc. Their dust-free and weather-resistant properties mean they can be used in clean rooms. These solid plastic compartments are also reusable and, when used frequently, can conserve resources and thus contribute to environmental protection, as they are difficult to recycle. The raw material is more expensive than cardboard and tools are also required for production.

Conclusion: ESD packaging with compartments made of solid plastic is well suited for clean rooms due to its dust-free properties. It is weather-resistant and can be reused very well.

Various materials can be used to manufacture ESD packaging and matching compartment inserts. The advantages and disadvantages of the individual raw materials should be tailored to the future area of application of the packaging in order to ensure the best possible protection of the products while guaranteeing environmental protection and cost-effectiveness.

Telephone consultation at:

036652-35496-0

In meander packaging, ESD films are glued into ESD cardboard boxes in a loop shape and serve as slots for electrical components. Meander packaging is particularly suitable for long and narrow components, as the smooth surface of the ESD film ensures that the components can be quickly “slid” into the individual loops of the film. Nevertheless, the meander shape protects the components from “sliding out,” as the loop shape counteracts this.

The advantage of meander packaging is that components of different lengths can be stored in one package if the entire package is lined with film. When developing product-specific packaging, the entire package does not need to be lined with ESD film in order to conserve resources; instead, it can be used only partially.

We now also offer our ESD film plug-in system in a meander shape as an environmentally friendly version made from 100% paper. The ESD film, which is glued into ESD cardboard boxes in a loop shape to create many slots for printed circuit boards or LED strips, among other things, has been replaced by antistatic paper. This means we can now offer a completely environmentally friendly and recyclable range of ESD packaging materials.

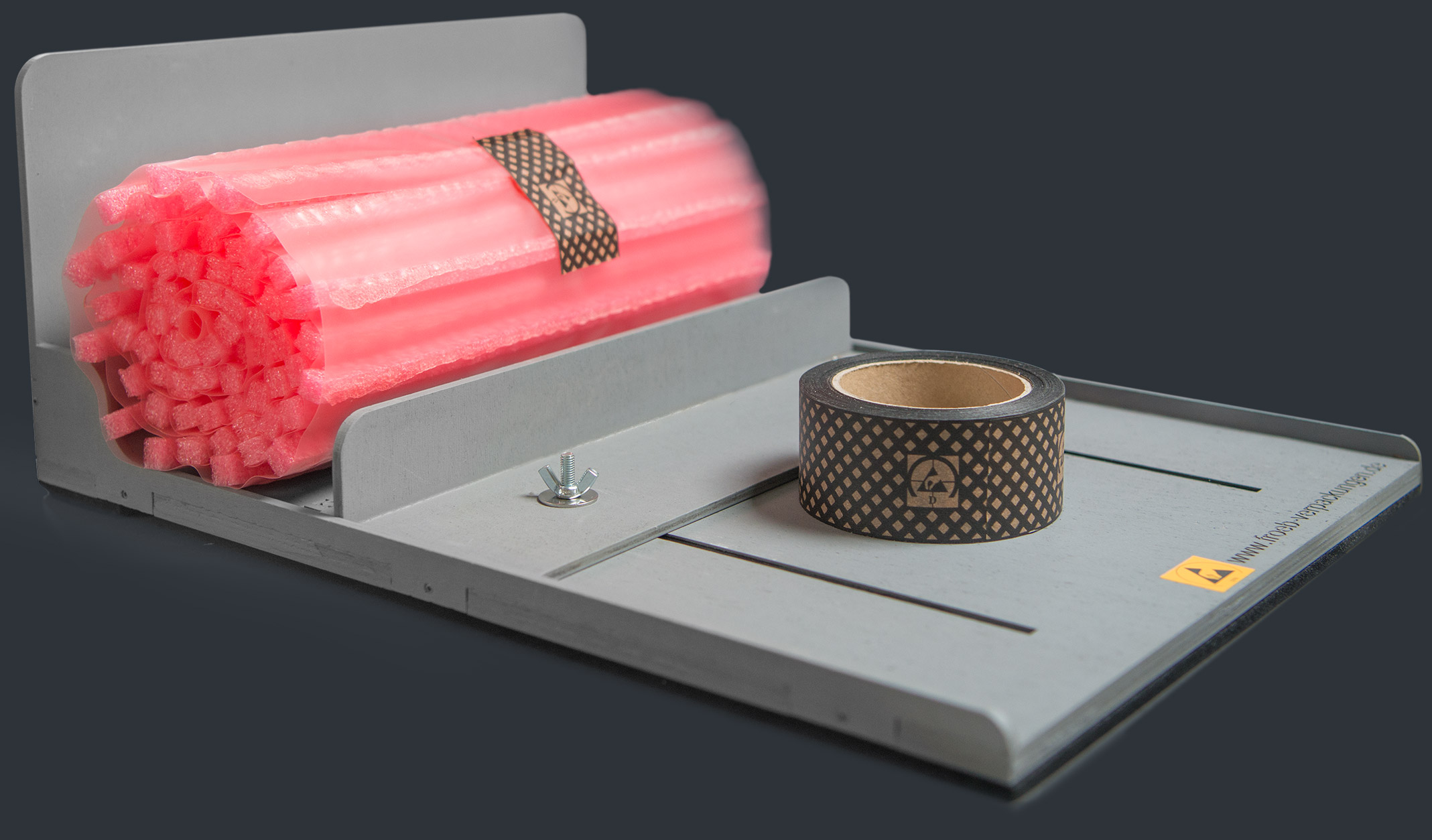

For fast and secure packaging of printed circuit boards, we have developed special wrap packaging in which foam elements are glued to antistatic film. This foam insert system is supplied in rolls and can be quickly adapted to the size of the printed circuit boards to be packaged using a simple packaging device. The size of the printed circuit boards is therefore irrelevant. The printed circuit board packages packed in this way can then be stored or transported easily and cost-effectively in standard transport containers. With this packing method, the amount of non-conductive plastic material used can be reduced to a minimum, which conserves resources and protects the environment. In addition, storage and shipping costs can be significantly reduced with this packing method.

Rapid packaging of printed circuit boards of all sizes and shapes

Rapid packaging of printed circuit boards of all sizes and shapes up to 35 printed circuit boards per packaging unit

up to 35 printed circuit boards per packaging unit low material consumption

low material consumption Cost-effective packaging, storage & shipping

Cost-effective packaging, storage & shipping  Material: Stratozell, antistatic, pink

Material: Stratozell, antistatic, pink Tooth strip: L x W x H 360 x 12.5 x 10 mm

Tooth strip: L x W x H 360 x 12.5 x 10 mm Height of grooves 7 mm

Height of grooves 7 mm Number of slots 35mm

Number of slots 35mm Distance between slots 10mm

Distance between slots 10mm

The starter set includes a packaging device, ESD wrapping film and ESD adhesive tape.

You will also find step-by-step instructions on how to use the wrapping packaging in our online shop.

Here you can take a look, how our wrapping-kit works. In this video is an older version.

Froeb-Verpackungen GmbH also offers environmentally friendly ESD bags and antistatic bags. These are made from antistatic paper in sizes 14.5 x 21 cm and 20.5 x 30 cm and are available with or without cushioning embossing.

To complete our range of ESD packaging materials, we offer ESD paper in two different versions. Standard ESD paper is available in rolls and cut-to-size sheets and can be used as a universal packaging material for electrical and electronic components. It is also used as an interlayer in ESD cardboard boxes or standard transport containers.

ESD cushioning paper is available in two different weights and can also be cut to size. Thanks to its stable, embossed structure, it has a particularly high cushioning effect and is therefore suitable as an environmentally friendly alternative to bubble wrap, as crumpled paper in ESD cardboard boxes and also as a practical and universally applicable packaging material for particularly sensitive electronic components.

The packaging developed and produced by Froeb-Verpackungen GmbH for electronic devices, assemblies and printed circuit boards is tested for its dissipative properties in accordance with the IEC 61340-2-3 (ANSI/ESD STM11.3 (a)) test method. At the customer's request, we also test the shielding effect of the packaging against electrostatic discharge. The test site set up for this purpose complies with the requirements of IEC 61340-4-8. Corresponding test reports can be provided.

Popular ESD products